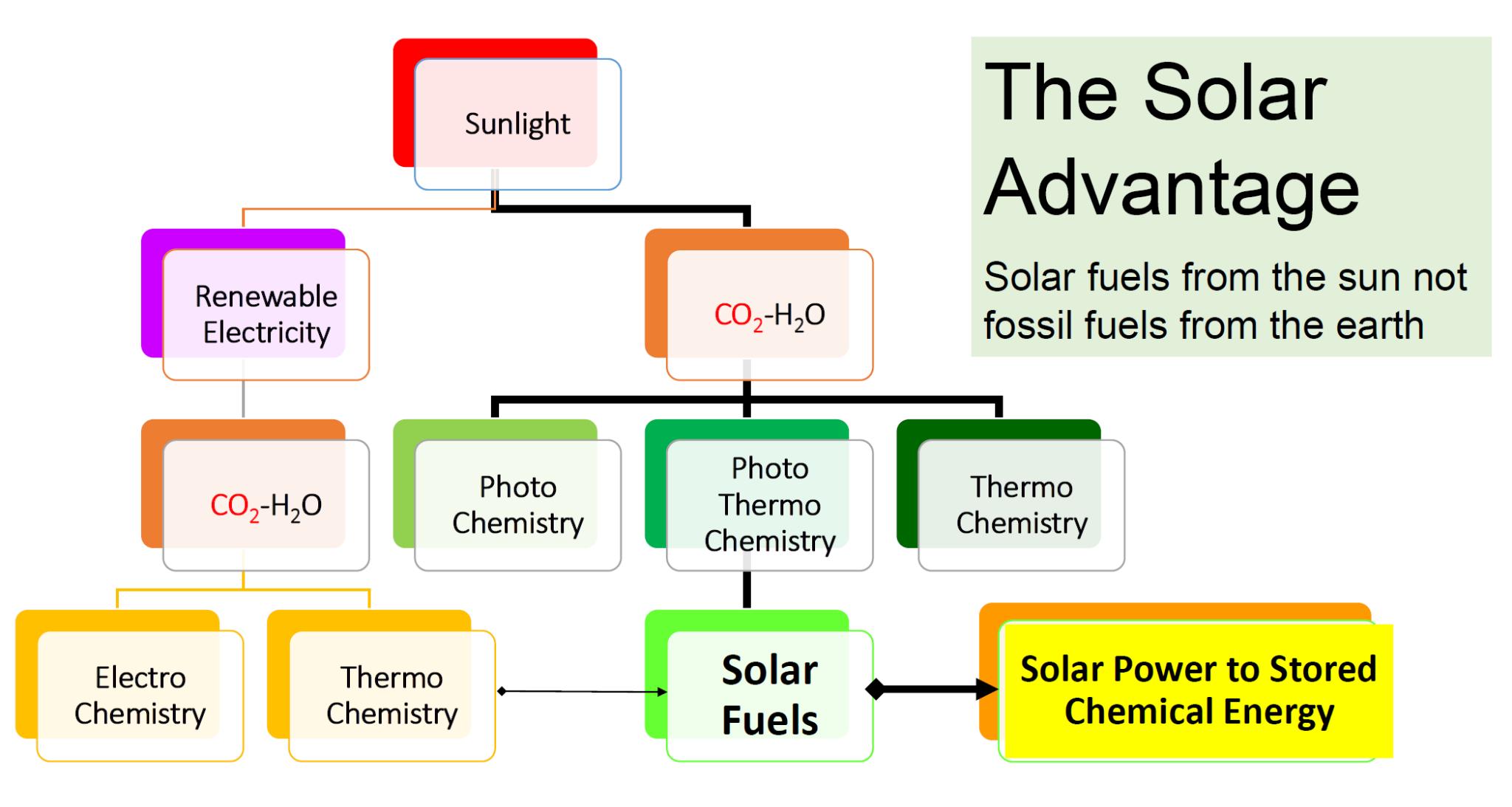

Our experience and intuition drove us to choose one of six viable approaches to enable the conversion of CO2 to fuels, namely, homogeneous catalysis, heterogeneous catalysis, bio-catalysis, photo-catalysis, electro-chemistry, photo-electrochemistry, solar thermal chemistry. We decided the clear choice was heterogeneous catalysis and the preferred source of power was sunlight. It is incredible to realize the sun bombards the Earth with enough light in one hour to satisfy our energy needs for a year. In the context of using sunlight to make fuel from carbon dioxide, it is important to appreciate the ‘solar advantage’. This concept, illustrated in the scheme, depicts the use of sunlight directly to convert CO2-H2O to solar fuels through photochemistry, thermochemistry or photo-thermal chemistry means. Compare this pathway to the indirect route of first converting sunlight electricity, which subsequently converts CO2-H2O to solar fuels through electrochemical or thermochemical means.

Our group decided that heterogeneous catalysis is the most practical route to developing CO2 solar refineries that, as a turnkey system, would seamlessly integrate with existing industrial infrastructure. To this end, we have been working on design rules and implementation strategies for the synthesis of novel classes of nanostructured materials with optimized composition, structure, size, shape and self-assembled architecture, in order to enable the heterogeneous catalytic conversion of gaseous CO2 to fuels. Our first breakthrough has been exploitation of the entire wavelength range of the solar spectrum, using photothermal heterogeneous catalysis to make efficient use of both the light and heat of the sun to drive the conversion.

To this end, we have developed a suite of solar-activated, nanostructured catalysts that facilitate conversion of CO2 into methanol, methane, and carbon monoxide. These catalysts enable the energy of the sun to be stored in the chemical bonds of the products, which, in many cases, offer a direct substitute for the fossil-based products used as automotive fuels or for electricity production. Furthermore, synthetic liquid fuels offer a significantly higher volumetric energy density than batteries and have the capacity to store daily and seasonally intermittent renewable electricity at a large scale, thereby helping to balance supply and demand on the electricity grid. This innovation outcompetes alternative solutions, and foresees modular, self-contained CO2 refining systems operating at industrial scales, and straightforwardly integrated into existing fossil-fuel-based infrastructure. These systems would operate as compartmentalized turnkey units to serve distributed emitters and remote communities with unique energy demands. This approach presents fast and flexible commercialization opportunities and is ideal for scale-up because such units can suit a wide range of applications, from individual households, to communities, to central power stations, thereby helping to mitigate financial risk. Our technological-readiness-level currently comprises engineered solar-powered methanol production and methane reforming lab-scale demonstration units, which are able to operate under industrially relevant conditions.

Through these small-scale, yet all-important, test reactors we can understand process performance in the presence of waste gases from existing industrial operations. A team of twelve young chemical engineering students is currently working on the energy and economic life cycle analysis of our envisioned solar powered CO2 refinery as their final-year capstone project. We have teamed-up with the U of T Central Steam Facility to integrate our solar-powered CO2 synthetic fuels system into their existing plant, in order to demonstrate the viability of our technology for reducing the carbon footprint of the university community. Such solar fuel refineries could help enable the energy transition toward a sustainable future by 2020. We are passionate and proud to work on this project as our social responsibility and for future generations.